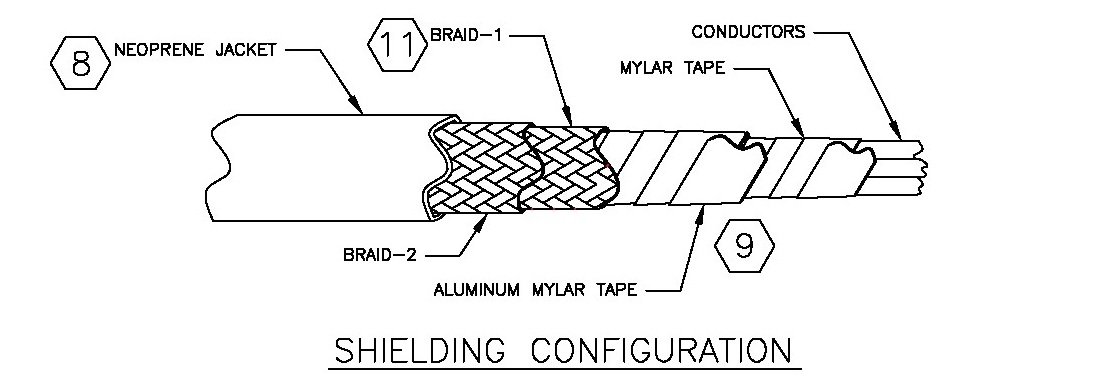

Electronic components for industrial and military applications must meet stringent EMI/RFI shielding requirements. FEC’s SCOLOR™ molded shield termination process is a true 360° soldered, metal-to-metal contact between the connector and tinned-copper shield braid. Using this process, our cables offer low RF impedance and high EMI shielding effectiveness not found with metal adapters, tension bands or multi-piece mechanical backshells. Our tinned-copper shield braids are woven directly onto the cable core using a braiding machine. This ensures a tight but flexible shield braid without solder joints or EMI windows.

SCOLOR Benefits

- Direct metal-to-metal, one-step 360° conductive bond between backshell and cable shield producing less than 1 milliohm of resistance.

- Adds rigid, low-profile support and strain relief to terminated wires at rear of connectors.

- Eliminates bulky multi-part RFI/EMI back shells, cable clamps and use of conductive epoxies.

- Available in configurations of 90°, 45°, straight, and various custom shapes.

- Can be applied to most metal connector types.