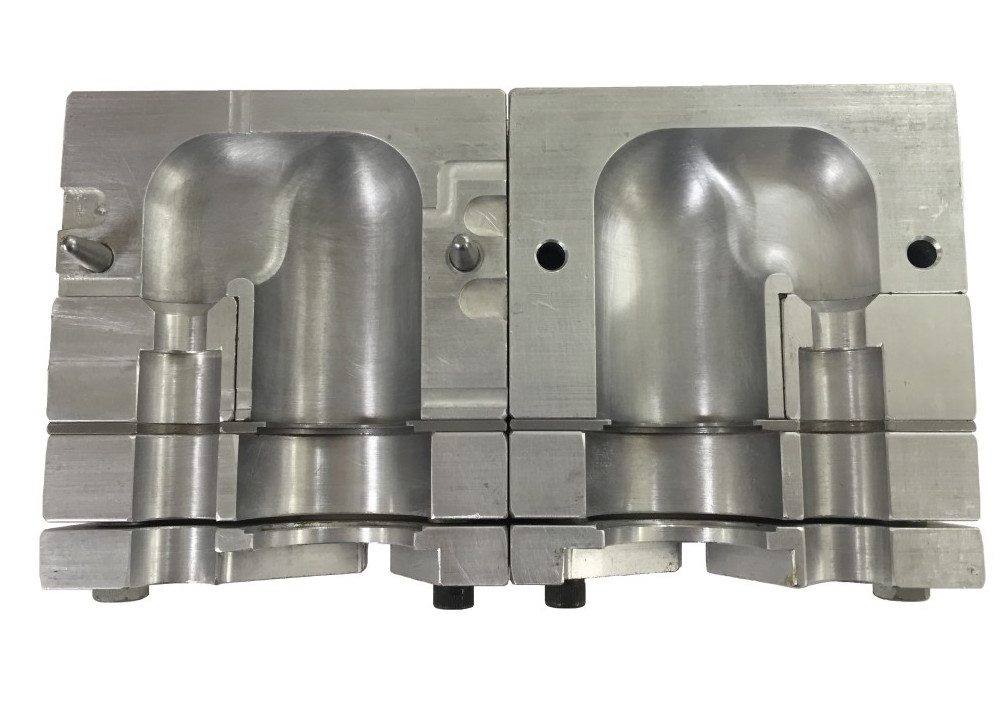

FEC is equipped and staffed to assume complete responsibility for fabrication and final installation or manufacture of your pre-designed systems. FEC’s 50,000 square foot cable assembly facilities include automatic and semi-automatic equipment for braiding and taping cables and harnesses, terminating wire leads, injection, compression, transfer and low-pressure molding of cable junctions, transitions and custom backshells. Our multi-million dollar inventory of custom mold tools will reduce the cost and lead time of your next custom cable requirements.

We can manufacture prototype and production quantities for our customers. FEC Sales and Engineering staff are available to offer technical support for prototype engineering and any other customer support requests. FEC assures that your final product will meet the highest standards by working closely with your Purchasing, Engineering and Manufacturing groups.